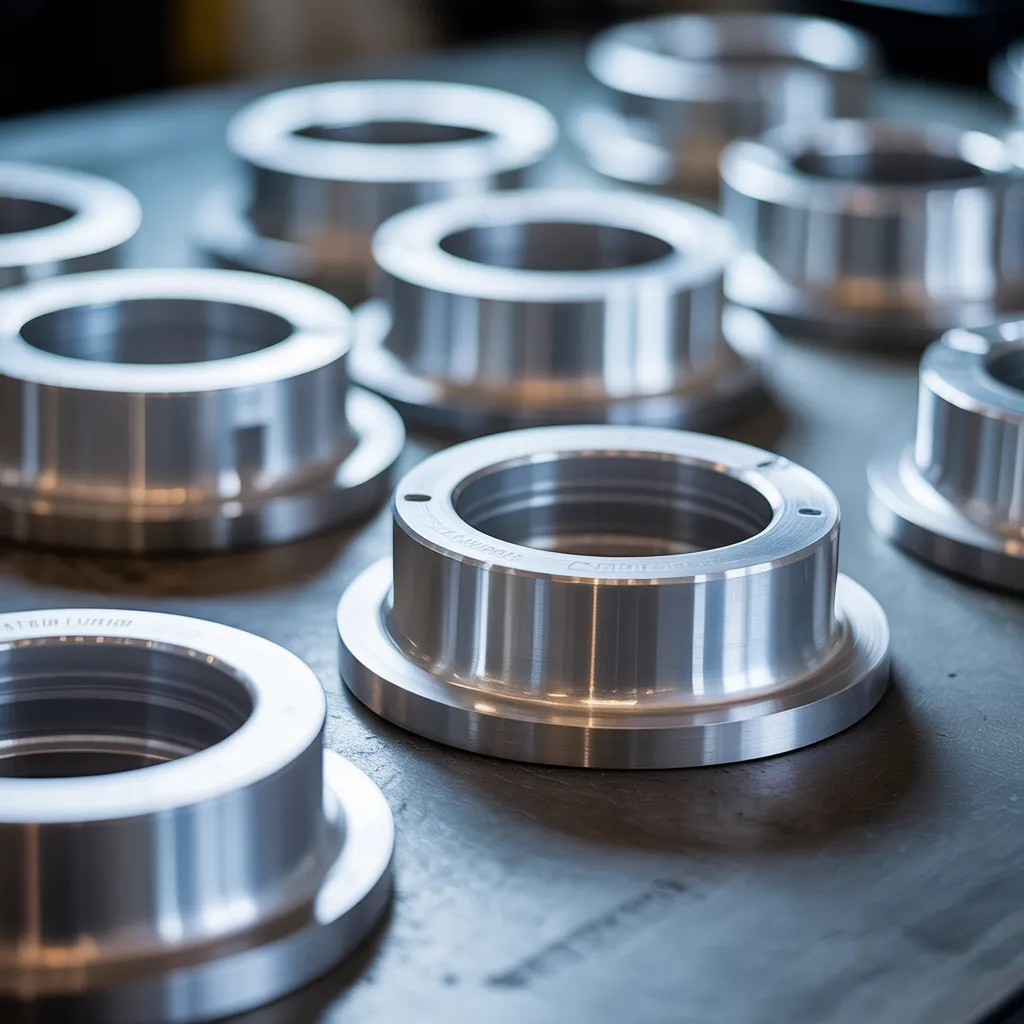

Permanent Mold Aluminum Castings: Precision Parts for Industrial Applications

Permanent mold aluminum castings serve a critical function in the production of precision components for various industries. These castings use reusable molds, producing exceptional accuracy and surface quality. As the demand for high-performance parts increases, understanding the complexities of this manufacturing process becomes essential. The strengths and applications of aluminum permanent mold castings merit further exploration, revealing their significance in modern industrial practices.

What You Should Understand About Aluminum Permanent Mold Casting

Despite the fact that several casting techniques exist, aluminum permanent mold casting proves superior for its ability to create superior components with superior dimensional accuracy. This approach employs reusable molds, generally manufactured from metal, which boosts thermal conductivity and enables rapid cooling of the molten aluminum. As a result, the process delivers intricate geometries and superior surface finishes compared to sand casting or other methods.

Permanent mold casting with aluminum is especially beneficial for creating components that demand reliable performance and longevity. The capability to manufacture pieces with exacting specifications makes it well-suited for industries like automotive, aerospace, and machinery. The process also minimizes waste, as the reusable molds can be utilized repeatedly, making it an eco-friendly option.

Manufacturing Aluminum Permanent Molds: The Process

Making aluminum permanent molds demands a precise and organized process that guarantees lasting quality and accuracy. Initially, a master pattern is created, often using materials for example wood or plastic, which serves as the foundation for the mold design. This pattern is then covered with a release agent to allow easy removal of the final mold.

Next, both halves of the mold are machined from high-strength aluminum, delivering precise tolerances and superior surface finish. After the halves are ready, they are joined, and any required cooling channels are installed to maintain temperature during the casting process.

The mold is subsequently exposed to heat treatment to boost its mechanical properties, prolonging its lifespan. Finally, the finished molds undergo rigorous quality control assessments to ensure their compliance with industry standards. This meticulous approach ensures that aluminum permanent molds can withstand the demands of repeated casting cycles while maintaining accurate dimensions and surface quality.

Key Advantages of Aluminum Permanent Mold Castings

Aluminum permanent mold castings deliver multiple important advantages that increase their desirability in manufacturing applications. Significant benefits feature better dimensional accuracy and an outstanding surface finish, which enhance the complete quality of the finished product. Additionally, the cost-effective production process makes these castings a practical choice for a variety of applications.

Enhanced Dimensional Accuracy

Accuracy in manufacturing processes is vital, and aluminum permanent mold castings stand out for their enhanced dimensional accuracy. This capability derives from the rigid molds used in the casting process, which maintain consistent dimensions throughout production. Aluminum's thermal conductivity also contributes significantly, facilitating rapid heat transfer that minimizes dimensional changes during solidification. Consequently, parts made through this method experience limited shrinkage and warping, resulting in tighter tolerances. Additionally, the repeatability of the permanent molds ensures that each casting conforms to the specified measurements, further enhancing accuracy. This level of precision is especially advantageous for industries demanding exact specifications, resulting in improved performance and reduced rework in manufacturing processes. Accordingly, aluminum permanent mold castings stand out for their dimensional integrity.

High-Quality Surface Finish Finish

Beauty and operational efficiency unite in the superior surface finish of aluminum permanent mold castings. This finish stems from the smooth surfaces generated during the casting process, which reduces post-processing requirements. The excellent surface quality improves the visual aspect of components, making them ideal for applications where appearance is essential. Additionally, a exceptional surface finish improves the performance characteristics of the cast parts, as it reduces friction and wear during operation. The uniformity of the finish also contributes to better adhesion for coatings and paints, guaranteeing longevity and durability. Overall, the excellent surface finish not only improves the aesthetic quality of aluminum permanent mold castings but also enhances their operational efficiency in numerous industrial applications.

Economical Production Method

The economical manufacturing process of aluminum permanent mold castings emerges as a notable advantage for producers. This technique decreases material waste through the use of reusable molds, thereby lowering total production costs. Additionally, aluminum's quick cooling in permanent molds enables reduced cycle times, enhancing production efficiency. The durability of the molds also contributes to cost savings, as they can withstand numerous casting processes without degradation. Consistent quality and lower defect rates benefit manufacturers by reducing rework and scrap levels. Moreover, producing complicated shapes without substantial machining processes further improves economic efficiency. All in all, aluminum permanent mold castings offer an affordable method for creating high-grade parts in multiple industrial sectors.

Comparing Aluminum Permanent Mold Castings against Traditional Techniques

Aluminum permanent mold castings offer distinct advantages over traditional casting methods, especially regarding production speed and surface finish quality. This efficient permanent mold approach permits accelerated completion times, making it ideal for high-volume production. Furthermore, the resulting surface finishes from aluminum permanent mold castings often surpass those achieved through conventional techniques.

Production Speed

Although traditional casting methods often involve extended processes and extensive setup times, aluminum permanent mold castings significantly enhance production speed. The utilization of permanent molds allows for rapid cycle times, as they can tolerate high temperatures and quick cooling rates, facilitating faster solidification of aluminum. This efficiency reduces the overall lead time for producing components, making it feasible for manufacturers to meet strict deadlines and increase output. Moreover, the reusability of permanent molds decreases the need for frequent mold creation, further streamlining the production process. Therefore, companies can respond more rapidly to market demands, maintaining a competitive edge in industries requiring high-volume production of precision parts. Overall, the speed of production with aluminum permanent mold castings is a substantial advantage.

Quality Surface Finishing

In comparing surface finish quality, aluminum permanent mold castings usually perform better than traditional casting methods as a result of their inherent design and production characteristics. The utilization of durable molds permits smoother surface finishes, minimizing the need for extensive post-processing. This generates fewer casting defects, such as porosity and surface irregularities, which are more common in sand castings. Furthermore, the rapid cooling rates associated with permanent molds result in finer grain structures, enhancing the overall surface texture. As a result, parts created through this method demonstrate superior dimensional accuracy and aesthetic appeal. Industries that emphasize surface quality, such as automotive and aerospace, continually favor aluminum permanent mold castings for their ability to fulfill stringent specifications without sacrificing production efficiency.

What Are the Applications of Aluminum Permanent Mold Castings?

Where does one discover aluminum permanent mold castings in real-world applications? These products are broadly applied in diverse sectors owing to their strength, dimensional accuracy, and superior surface finish. Standard applications include motor vehicle components such as engine blocks, transmission cases, and structural parts, where durability and lightweight characteristics are vital. Moreover, they are applied in the aerospace domain for components including brackets and housings, which require superior precision and weight minimization.

In the consumer goods market, aluminum permanent mold castings are frequently present in products including cookware, sporting equipment, and electronic housings. They also serve an important function in the manufacturing of industrial machinery parts, including pumps and valves, where reliability and performance are paramount. The versatility of aluminum permanent mold castings makes them an indispensable option across multiple sectors, ensuring the production of high-quality, functional parts customized for specific applications.

Essential Design Points for Accurate Aluminum Castings

Engineering precision aluminum castings requires thorough consideration of multiple key factors to ensure superior performance and functionality. One crucial aspect is the selection of correct alloy compositions, which determine mechanical properties, corrosion resistance, and thermal conductivity. Designers must also address the geometry of the components; complex shapes may call for specialized mold designs to avoid defects and maintain uniform cooling.

In addition, wall thickness ought to be optimized to equilibrate strength and weight, stopping excessive material use while upholding structural integrity. Surface finish is a vital consideration, as it affects both aesthetic appeal and functionality. Correct draft angles should be incorporated to facilitate mold release without harming the castings. Finally, tolerances need to be defined accurately, as precision in dimensions critically determines assembly and operational efficiency. By implementing these design considerations, manufacturers can create high-quality aluminum castings suitable for a wide range of industrial applications.

Emerging Trends in Aluminum Permanent Mold Casting Technology

Major advancements in aluminum permanent mold casting technology are on the horizon, motivated by the need for enhanced efficiency and sustainability in manufacturing processes. Developments in mold materials, such as the implementation of advanced ceramics and composites, are projected to elevate durability and thermal performance. Automation and robotics will play a crucial role in streamlining production, minimizing labor costs, and increasing precision. In addition, the integration of artificial intelligence and machine learning will optimize the casting process, permitting real-time monitoring and adjustments to guarantee superior quality begin now control.

Eco-friendly methods, like the reclamation of aluminum scrap and power-saving melting techniques, will probably become standard. Furthermore, developments in 3D printing will support fast prototyping of molds, enabling quicker iterations and tailored designs. On the whole, these trends indicate a significant shift in aluminum permanent mold casting, matching the wider manufacturing industry's goals of productivity, sustainability, and technological advancement.

FAQ

Which Industries Benefit Most Significantly From Aluminum Permanent Mold Castings?

Aluminum permanent mold castings provide significant advantages to the automotive, aerospace, and machinery industries aluminum permanent mold castings. Such sectors make use of the precision, durability, and lightweight properties of castings to enhance performance and efficiency in their specific products and applications.

Can You Tell If Aluminum Permanent Molds Be Used Again?

Indeed, aluminum permanent molds can be reused repeatedly. Their lasting quality and ability to withstand wear enable multiple casting cycles, positioning them as a budget-friendly solution for manufacturing superior components across multiple manufacturing applications.

How Does Temperature Affect Aluminum Casting Quality?

Temperature considerably impacts aluminum casting quality; increased temperatures can improve fluidity, minimizing defects, while excessively high temperatures may trigger oxidation and weaken structural integrity. Keeping ideal temperature delivers better dimensional accuracy and surface finish in castings.

Which Additional Finishing Procedures Are Necessary After Casting?

Following the casting process, further finishing operations may involve machining, surface treatment, cleaning, deburring, and polishing. These operations refine dimensional accuracy, improve surface finish, and confirm the final product fulfills specific performance and aesthetic requirements.

Are Aluminum Permanent Mold Castings Good for the Environment?

Aluminum permanent mold castings are generally considered eco-friendly due to their ability to be recycled and reduced energy consumption during the manufacturing process. Their longevity also results in reduced waste, supporting sustainable practices in industrial applications.